Taiwan type H-1816Taiwan type

H-1816 Heavy Band saw machine

* All specifications, dimensions and design characteristics shown in this catalogue are subject to change without prior notice.

Machinery Main parts list

Machine Features

Structure

• Oversized precision ground, Big column support and guide the rugged saw head through the entire cutting cycle.

• Cross link connecting two columns for enhanced structural strength

• Dual hydraulic work vice

Blade Drive

• Specially designed gearbox for high lateral pressure

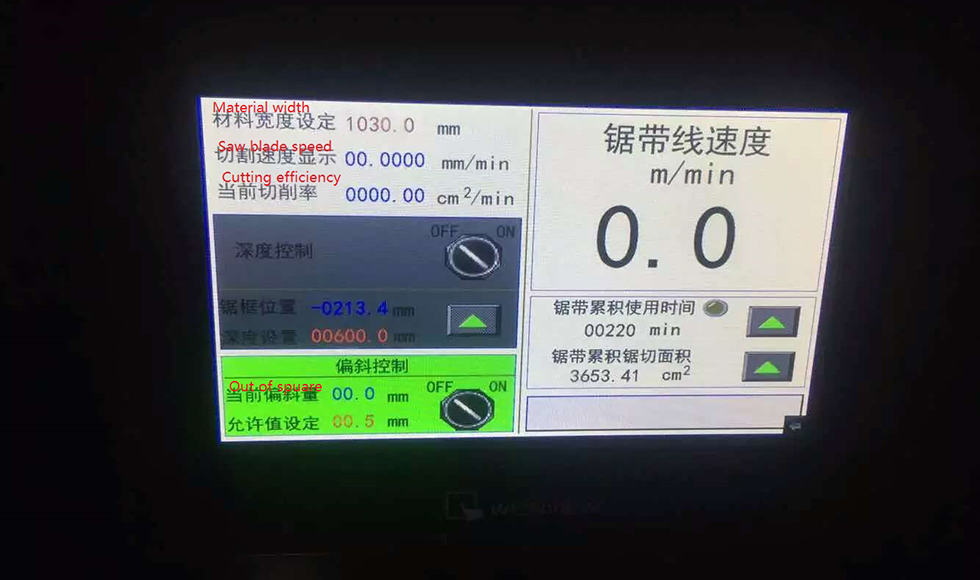

• Inverter controlled infinitely variable blade speed

Blade Guidance & Lubrication System

• Carbide blade guides with bearing guides

• Two additional guides to support the blade from the top

• Automatic hydraulic blade tensioning device

• Integral coolant system

• Pitch design for coolant drainage

• Power blade brush

Material Feeding & Clamping

• Hydraulic front and rear vises

• Ductile cast iron vises with replaceable hardened wear plates

Safety

• Proximity switch for sensing blade slippage or breakage

• Interlock design in electrical and hydraulic system

• Conduits protection measure

• "Alert Orange" safety measure

Standard Accessories

• Additional flushing hose

• Bi-metal saw blade

• Built in work light

• Tool box, and an additional wire brush

• Operation & parts manual

| Model | H-1816 | |

| Capacity | ● | 1600 mm |

| ■ |

1800 x 1600 mm min. clamp width 600 mm |

|

| Blade Speed | 12 to 60 m/min. (INVERTER) | |

| Motor | Blade Drive | 15 kW |

| Hyd. Pump | 5.5 kW | |

| Coolant Pump | 0.4 kW | |

| Blade Size | 15900 x 80 x 1.6 mm (626" x 3" x 0.063") | |

| Blade Tension | Hydraulic | |

| Index Length | 1800 mm (70.9") | |

| Machine Weight | 33000 kg (72600 lb) | |

| Floor Space (L x W) | 7610 x 4700 mm (299.6" x 185") | |

Machinery Main parts list

| Item | Name | Specification | Quantity | Manufacturer |

| 1 | Frequency motor for main motor use | 15 kw | 1 set | Germany SEW |

| 2 | Transducer (inverter) | 15 kw | 1 set |

Taiwan SHIHLIN or SIEMENS |

| 3 | Main hydraulic parts (oil pump motor group; magnetic valves) | 1 Unit |

SEVENOCEAN(Taiwan) OIL Motor CHYUN TSEN(Taiwan) |

|

| 6 | Gear box | 1 Unit | Germany SEW | |

| 7 | chip conveyor | 1 set | Yiantai Chongyan machinery | |

| 8 | Bearing | NSK or NTN (Japan) | ||

| 9 | Control electrical device | 1 Unit |

PLC MITSUBISHI (Japan)Contactors: TECO(Taiwan)Switches: Schneider Electric |

Structure

• Oversized precision ground, Big column support and guide the rugged saw head through the entire cutting cycle.

• Cross link connecting two columns for enhanced structural strength

• Dual hydraulic work vice

Blade Drive

• Specially designed gearbox for high lateral pressure

• Inverter controlled infinitely variable blade speed

Blade Guidance & Lubrication System

• Carbide blade guides with bearing guides

• Two additional guides to support the blade from the top

• Automatic hydraulic blade tensioning device

• Integral coolant system

• Pitch design for coolant drainage

• Power blade brush

Material Feeding & Clamping

• Hydraulic front and rear vises

• Ductile cast iron vises with replaceable hardened wear plates

Safety

• Proximity switch for sensing blade slippage or breakage

• Interlock design in electrical and hydraulic system

• Conduits protection measure

• "Alert Orange" safety measure

Standard Accessories

• Additional flushing hose

• Bi-metal saw blade

• Built in work light

• Tool box, and an additional wire brush

• Operation & parts manual